Where is the precision?

becomes the standard...

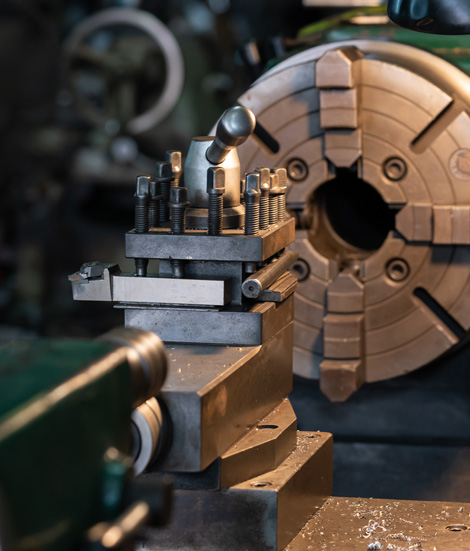

Wire EDM (EDM) machining for the most demanding parts, geometries and materials.

Micron accuracy, without compromise.

Welcome to Erozimat

A rounded production cycle with a trusted team

Certificates

Erozimat doo has ISO 9001 certificates that confirm business operations in the direction of achieving the projected and expected level of quality of products and services. These certificates enable us to be competitive both on the domestic and foreign markets. .

ISO9001:2015

Premium class, Guaranteed

Year

A company with experience

Projects

100% satisfaction

Engineer

Top engineers are the foundation of our company

Innovative technology

Our goal is simple: the perfect combination of precision, durability and aesthetics.

Innovative technology

Our goal is simple: the perfect combination of precision, durability and aesthetics.

We deliver on time.

Our process is optimized to ensure fast turnaround and reliable delivery, without compromising quality.

We deliver on time.

Our process is optimized to ensure fast turnaround and reliable delivery, without compromising quality.

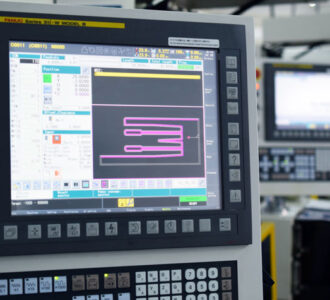

Precision in every detail

Our experts use modern machines and control systems that ensure accuracy down to the smallest millimeter. Every product goes through strict quality control, because we know that trust is built in the details.

Precision in every detail

Our experts use modern machines and control systems that ensure accuracy down to the smallest millimeter. Every product goes through strict quality control, because we know that trust is built in the details.

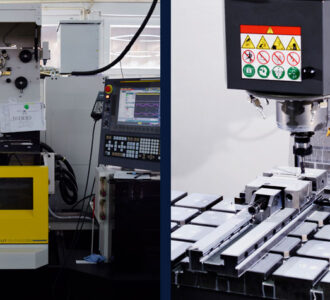

Today, Erozimat doo has several erozimats with different characteristics, a complete machine workshop, complete equipment for quality control, hardware, software for designing and programming, as well as highly trained personnel. The directions of further development are directed towards the constant modernization of technology in these areas, towards the improvement of existing and employment of new personnel, and therefore the increase of production capacity.

Our production management process

-

01

Reception of requests and analysis of documentation

-

02

Planning and development of technology

-

03

CAD/CAM preparation and programming

-

04

CNC processing and assembly of assemblies

-

05

Quality control and delivery

Latest on the blog

- Tools and Machines

- Interesting facts

- Metalworking

- News

- Software

- November 22, 2025

- Milos